Customer story

Labee Group: 'The new tanks have enabled us to cope with the current demand for storage'

Three 1,000 m3 duplex tanks for Labee Group

Since its inception, Labee Group has been producing products made of wood, wood shavings and sawdust in Europe. Supplier demand for tank storage prompted the company to extend its business activities by setting up Tank Storage Moerdijk. The need for new stainless steel storage tanks subsequently arose.

Bram van Engelen, Head of Technical Service at Labee: ‘Our primary aim was to add new tanks for the benefit of our own wood products in order to be able to buy up and store larger volumes of vegetable oil, and we soon found ourselves heading in a new direction. Through Tank Storage Moerdijk, we started offering storage tanks for vegetable and mineral oils in 2021. We’re conveniently located on the water, enabling us to load and unload tanker vessels straight away. Our array of tanks initially comprised used tanks, but we soon realised that these are only available in limited quantities. So we started looking for newly constructed ones and ended up in touch with Gpi.’

‘I’m looking forward to collaborating with Gpi again in the future’

The request

Bram describes the early stage: ‘We approached several parties, Gpi included. Gpi visited us to survey the situation and discuss the outline designs. Which they then set to work on. We were swayed towards choosing Gpi because of both the pricing and their rapid turnaround time. Gpi proved to be not only the most inexpensive but also the most effective. Swift progress was made, and we’d soon gone from our A4 sketch to a 3D drawing, quote and the construction of the tanks. It all came together in a short space of time.’

Duplex tanks

The assignment consisted of three storage tanks made of stainless steel duplex 1.4062. Bram explains why duplex was selected: ‘Duplex was the best option from a price perspective as the material is more robust and can be kept thinner as a result. A large amount of material goes into a tank. If you’re able to use stronger material to produce a thinner tank, then considerably less material will be required. This was the most economical option.’

About the tanks

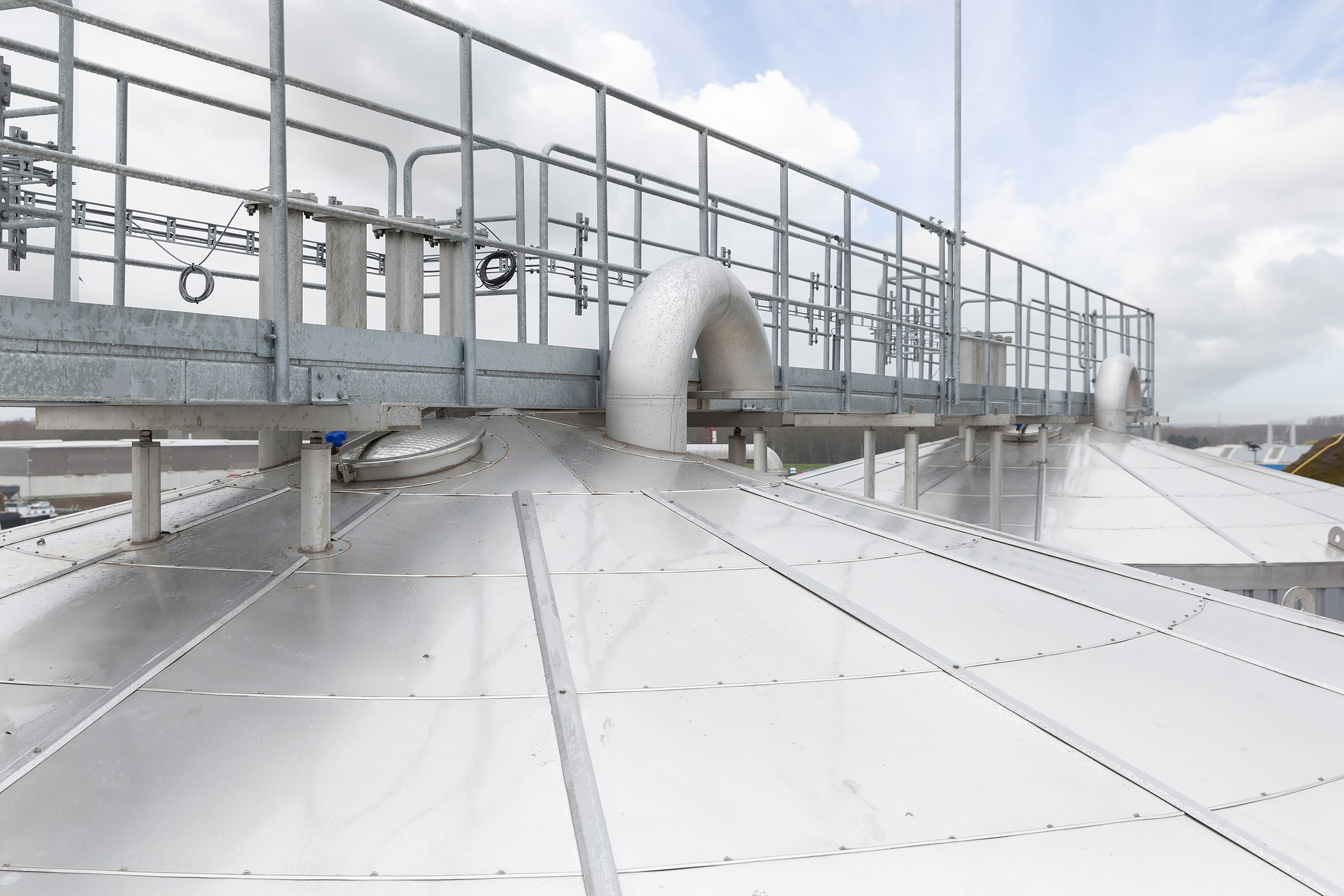

The tanks are 20 metres tall in total and have a diameter of 8.6 metres. They have a storage capacity of 1,000 m3 and are well suited to storing vegetable oils. Bram discusses the storage tanks: ‘The storage tanks are equipped with heating and insulation and have been finished with steel plating and coated in the colour of Labee Group’s adjacent building. Lending them the same image as our premises. Another unique detail about the tanks is that the measuring gauges have been raised above the tanks. This was done during the engineering phase and the people who work with them on a daily basis really appreciate it now. The spiral staircase and walkways supplied by Gpi ensure that the tanks are readily accessible.’

Transport & installation

‘We were keen to see whether they’d actually manage to meet the turnaround time, but in the end they even managed to deliver a week earlier. The transport went smoothly. We did the installation work ourselves and solid prep work by both parties made this a plug-and-play affair’, says Bram. He continues: ‘They lived up to every agreement, including in terms of price and turnaround time, and the service subsequent to delivery has been good too. Even if I send a project engineer a query now asking for information on the tanks, I’ll have that information in my inbox a couple of hours later.’

‘They lived up to every agreement and the service subsequent to delivery has also been good’

The result

Bram details the outcome: ‘We’re delighted with the new storage tanks when it comes to both image and ease of use. The tanks are being used at the moment for storing rapeseed oil which will be used by our customer for biofuel. The new tanks have enabled us to cope with the current demand for storage for the time being.’

The collaboration

Bram is enthusiastic about the collaboration with Gpi: ‘I had a good feeling about it right from the outset. They were genuinely interested, they contributed their ideas and it’s great that the communication channels are streamlined. Meaning you don’t have to keep repeating your story. Gpi makes things hassle-free in that regard. The communication is fast and pleasant. I’m looking forward to collaborating with Gpi again in the future.’