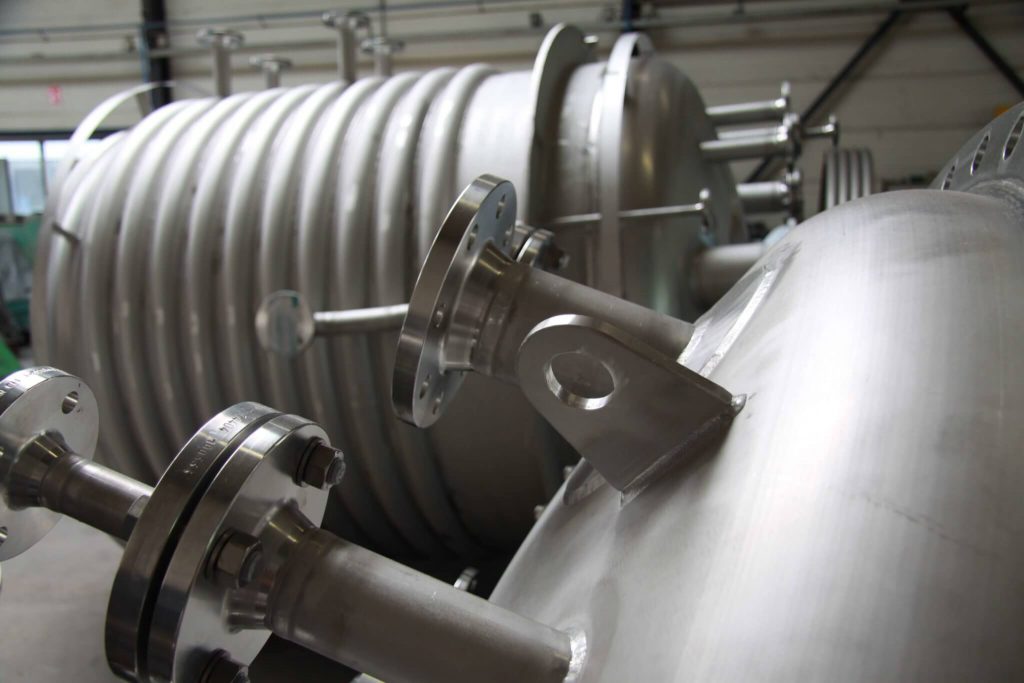

Stainless steel chemical tanks and reactors

Stainless steel storage tanks for the chemical industry

Stainless steel chemical tanks and reactors for the chemical industry are often subjected to tough conditions. Equipment can be subject to great temperature fluctuations, while holding highly corrosive contents and withstanding high pressures or a vacuum. Explosion risks may also play a role. Because of this, reliability, durability and safety are always paramount when designing and manufacturing these tanks.

Equipment to rely on

When manufacturing chemical tanks and reactors for the chemical industry, there are often special requirements. The tanks must, for example, be able to withstand: high pressures (or even a vacuum), large temperature differences and highly corrosive or abrasive contents. Explosion risks may also play a role. As the specialist in the design and production of tanks and reactors, we are able to fulfil even the strictest of requirements and standards. This allows us to build PED-certified stainless steel pressure vessels entirely ourselves.

Quality and assurance

Gpi not only builds a variety of reactors and pressure vessels, but also shop-built storage tanks or site fabricated tanks up to 15,000 m3 for chemical products. Our methods and processes enable us to satisfy the most stringent requirements and standards. This allows us to build PED-certified pressure vessels according to norms such as the EN13445 or AD2000, large flat bottom tanks according to EN 14015 or API 650 and KIWA tanks according to BRL-756.

By having engineering, production and quality control in-house, we are able to supervise qulity to the greatest extent possible and guarantee solutions which satisfy the most stringent requirements. Aside from the workmanship of our products, the documentation and material traceability of our products is of the highest standard. Naturally, we adhere to mandatory standards and regulations. Every audit is welcomed.

Do you have any questions about our chemical tanks / reactors?

KIWA BRL-K756

Since 2008, chemical storage installations in the Netherlands must legally comply with the BRL-K903/08 standard. In these installations, vertical steel stanks of up to 150,000 m3 are required to comply with the BRL-K756-3 directive. Gpi is certified by KIWA in order to be able to design and build tanks according to customer specifications that comply with relevant standards.

PGS 29,30,31

Does your installation need to comply PGS 29 / 30 / 31 regime? We would be happy to help with what this means for your tank.

From stainless steel storage tank to reactor

In addition to storage tanks up to 15,000m3, Gpi builds related process equipment to specification. This includes reactors, process vessels, heat exchangers, evaporators, flash vessels etc., for both powders and liquids.

Ourstainless steel tanks for chemicals

View the tanks and equipment that we build for the chemicals industry