Cosmetics

Reliable products

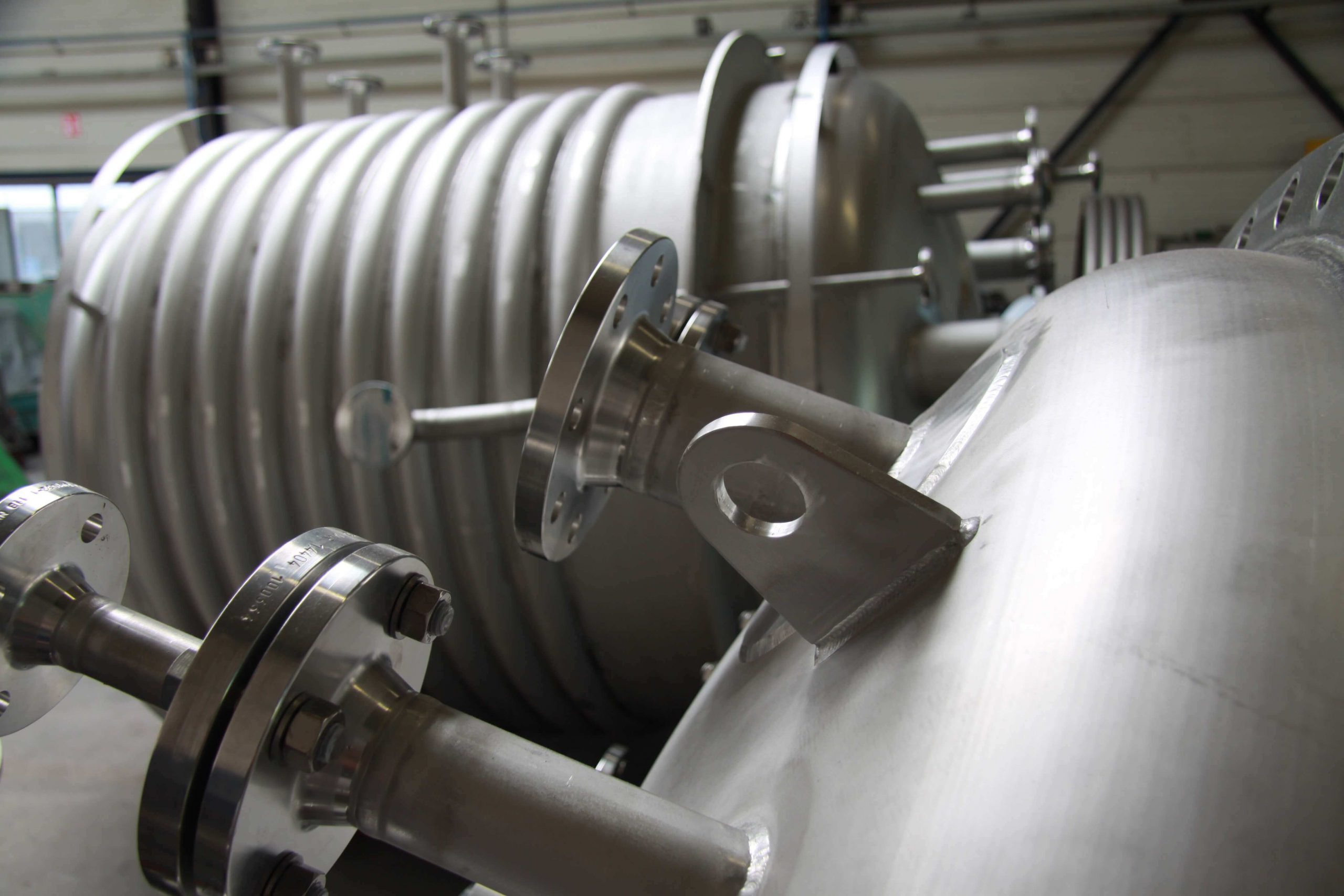

With rapidly-changing demands in the consumer market, it is important to have flexible and custom-made equipment solutions. Here, the delicate structure of the products must be taken into account when heating, cooling or mixing them. We will actively collaborate with you when thinking about the tank design, and about specific tank/agitator combinations which will have a positive impact.

Hygiene and high-grade design

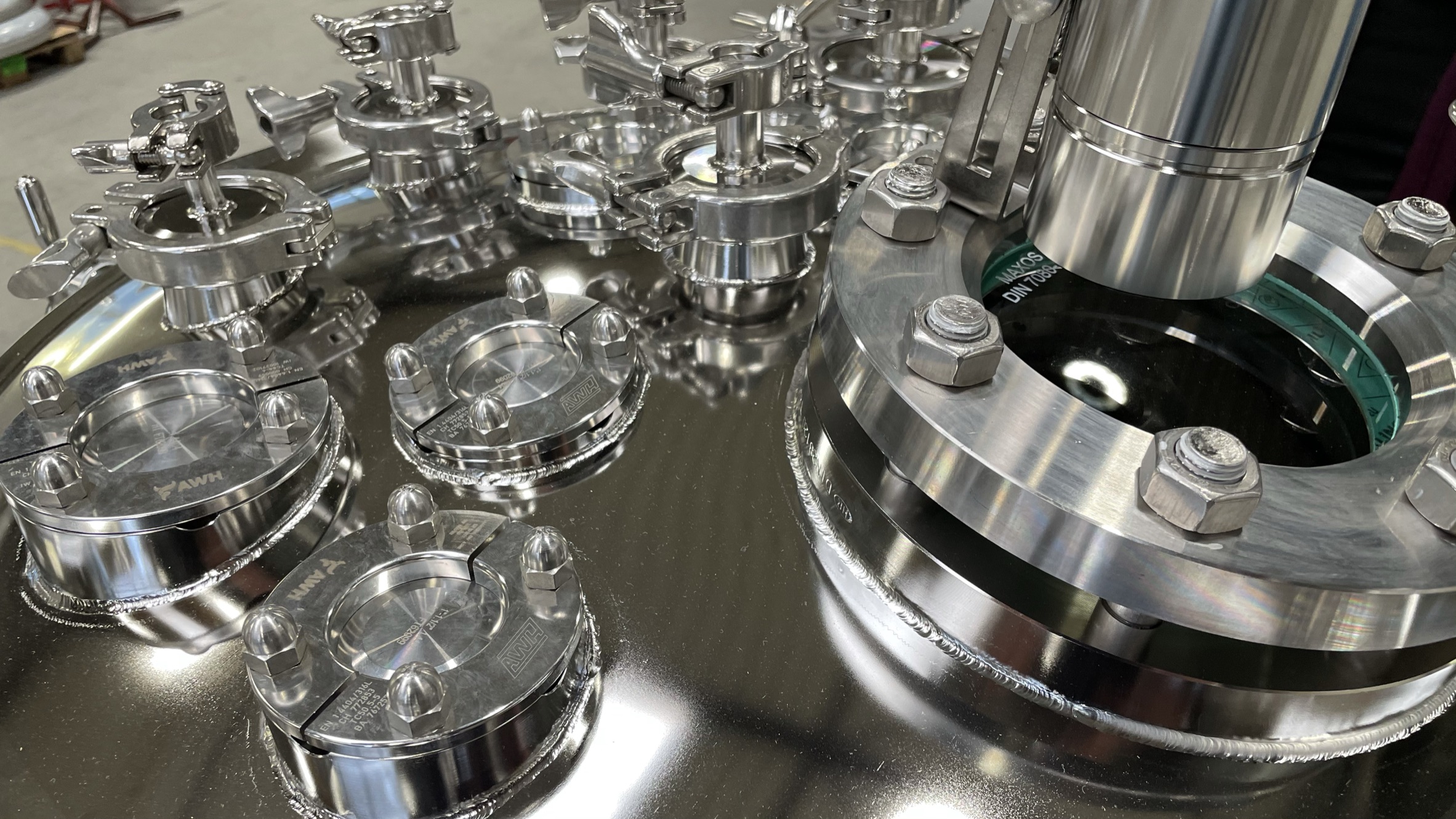

Gpi supports the development and production of high-grade process equipment. Our technical specialists are often involved as advisors in the early stages of developing new installations for an optimal tank or process design, and selection of the correct appendages. This applies to tanks such as WFI tanks, mobile process vessels or product storage tanks.

By having engineering, production and quality control in-house, we are able to supervise quality to the greatest extent possible and guarantee you solutions which satisfy the most stringent requirements. Aside from the workmanship of our products, the documentation and material traceability of our products is of the highest standard. Naturally, we adhere to mandatory standards and regulations. All and any audits are welcome.

Documentation and material traceability

We ensure quality of your products via comprehensive documentation files. Naturally, the origin of all our materials is automatically documented. Reassure yourself of our quality and request an audit.Read more about our quality and certification here.

Do you have any questions about our

cosmetic tanks?

Mixing, pressure, heating/cooling and hygiene

Process vessels or reactors are complex tanks which, despite their often limited volume, require a great deal of work. Ask our engineers to help selecting the optimal combination of mixing, pressure, heating/cooling and hygiene. They have the right experience in order to aid you in terms of selecting the correct types of connectors, optimal spraying ball positioning and degree of finish. If your tank is to be implemented in a clean room, we can also discuss an hygienic exterior design with you.

View the most common types of tanks which we create for the cosmetics industry, or view our most recent products.

Our products for cosmetics

View the tanks that we build for the cosmetics industry