Process Tanks

The Right Tank for Any Industry and Any Process

Chemical, mechanical or physical processes take place in all industries and tanks are almost always involved. We have the knowledge needed to turn the required process into an efficient and effective tank design.

Tanks for All Processes and Industries

Process vessels or reactors are always complex storage tanks in which a range of factors play a role. Allow our engineers to collaborate with you in order to find the optimal combination of factors, such as the mixing of powders or litres of liquids, pressure, heating/cooling and hygiene.

They have the experience in order to aid you in terms of selecting the correct types of connectors, optimal spraying ball positioning and the correct finishing level.

Our engineers are also aware of all typical stainless steel tank designs, equipment, and appendages that are applicable in your industry, whether this concerns mobile process vessels for the pharmaceutical industry or CCT tanks for the beer industry.

Do you have any questions about our process tanks?

Our engineering and production departments can satisfy the most stringent requirements and standards. This allows us to design and manufacture PED-certified industrial pressure vessels entirely ourselves in accordance with NEN-EN13445 and AD2000.

By having engineering, production, and quality control in-house, we are able to supervise quality to the greatest extent possible and guarantee solutions that satisfy and complete the most stringent requirements.

Aside from the workmanship of our products, our documentation and material traceability of our products is of the highest standard.

Storage Tank and Agitator Combinations

We can supply the agitator as well as the tank. Gpi has an excellent working relationship with all reputable agitator suppliers for problem-free processing and precise integration with the tank design and assembly.

Finishing Level

As a standard, Gpi ensures a high finishing level. For some applications, such as in the food industry or even in the pharmaceutical industry, specific requirements are applicable.

As a standard, food tanks are produced with an internal roughness of Ra 0.8, but if desired, we can also produce tanks with much smoother (and therefore more hygienic) inner walls.

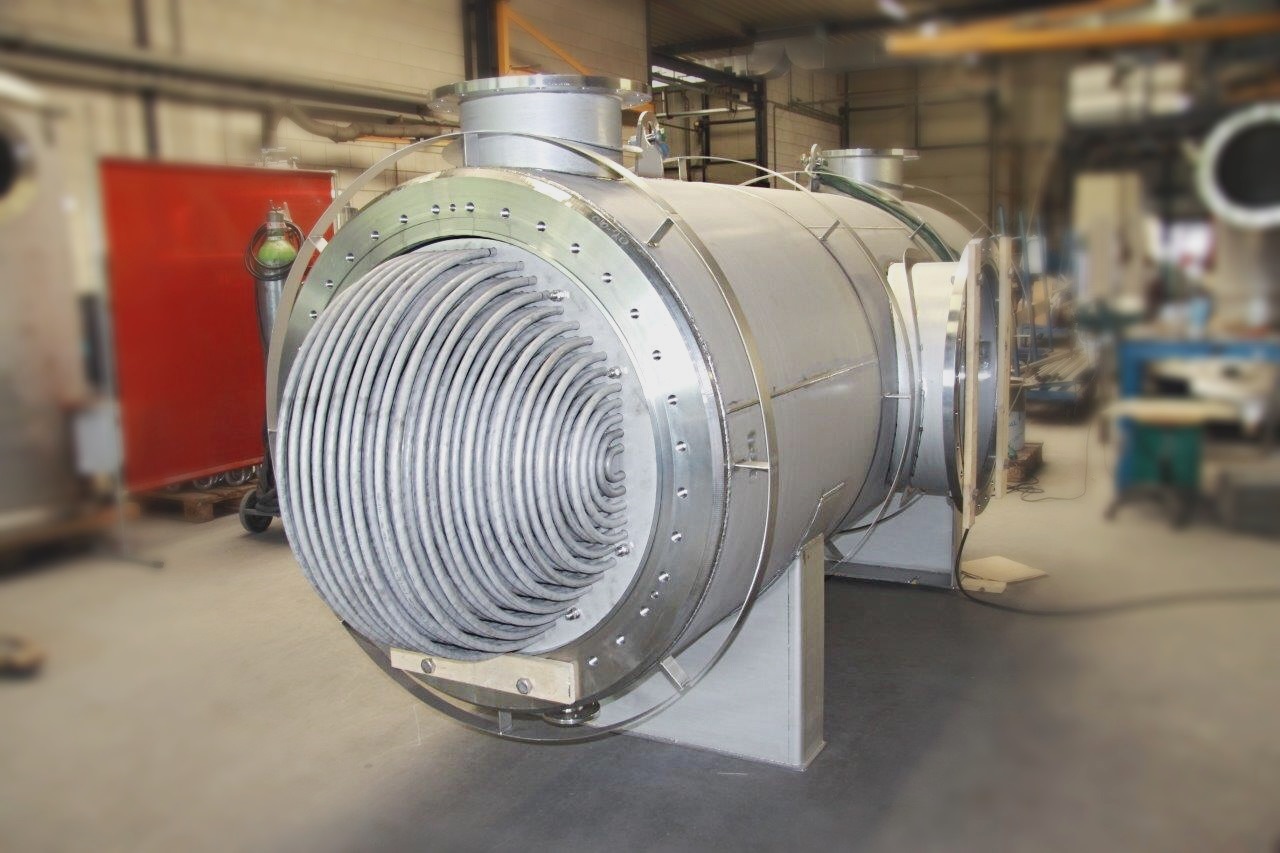

Heating and Cooling

For processes such as pasteurisation and fermentation, heating and cooling of the tank are crucial. We ensure the correct combination of heating/cooling capabilities and an insulation system for the tank in order to heat or cool your product within the desired time frame.

Please let Gpi know directly what heating/cooling capacity you require for your project, and we will collaborate with you in order to arrive at the most efficient solution, whether this concerns a dimple, a double wall, or a half pipe.