Stainless steel tanks for dairy

More than milk

The dairy market has experienced rapid growth in the past few years, and the large range on offer requires efficient processing. For this purpose, a good tank design ensures good longevity of the product and low maintenance costs. In addition to this, during processing of raw milk to end product, small differences in the design, or specific tank agitator combinations, can lead to big differences in the treatment of the product.

Experience in dairy tanks

Over the past 20 years Gpi has produced just about every type of dairy tank or equipment type for almost every major dairy brand in the world. We understand the processes, know the typical tanks used and automatically deliver the expected quality and finish. We design, build and assemble tanks and equipment for handling all types of raw milk, butter, cheese, yoghurt and ice cream, to baby food, milk powder, whey and other derivatives.

Do you have any questions about dairy industry tanks and equipment?

By having engineering, production and quality control in-house, we are able to supervise quality to the greatest extent possible and guarantee you solutions which satisfy the most stringent requirements in terms of hygiene, product longevity, safety and operating convenience, for both liquids and solids. Building, testing and making your equipment operational on location is no problem at all for our assembly department. Naturally, we adhere to international standards and regulations, and if required we can also manufacture our equipment according to EHEDG guidelines.

Tank agitator combinations

We can supply the agitator as well as the tank. Gpi has a good working relationship with all reputable agitator suppliers for problem-free processing and assembly.

Finishing level

As a standard, we produce our food tanks with an internal roughness of Ra 0.8, but if desired we can also produce tanks with much smoother (and therefore hygienic) inner walls.

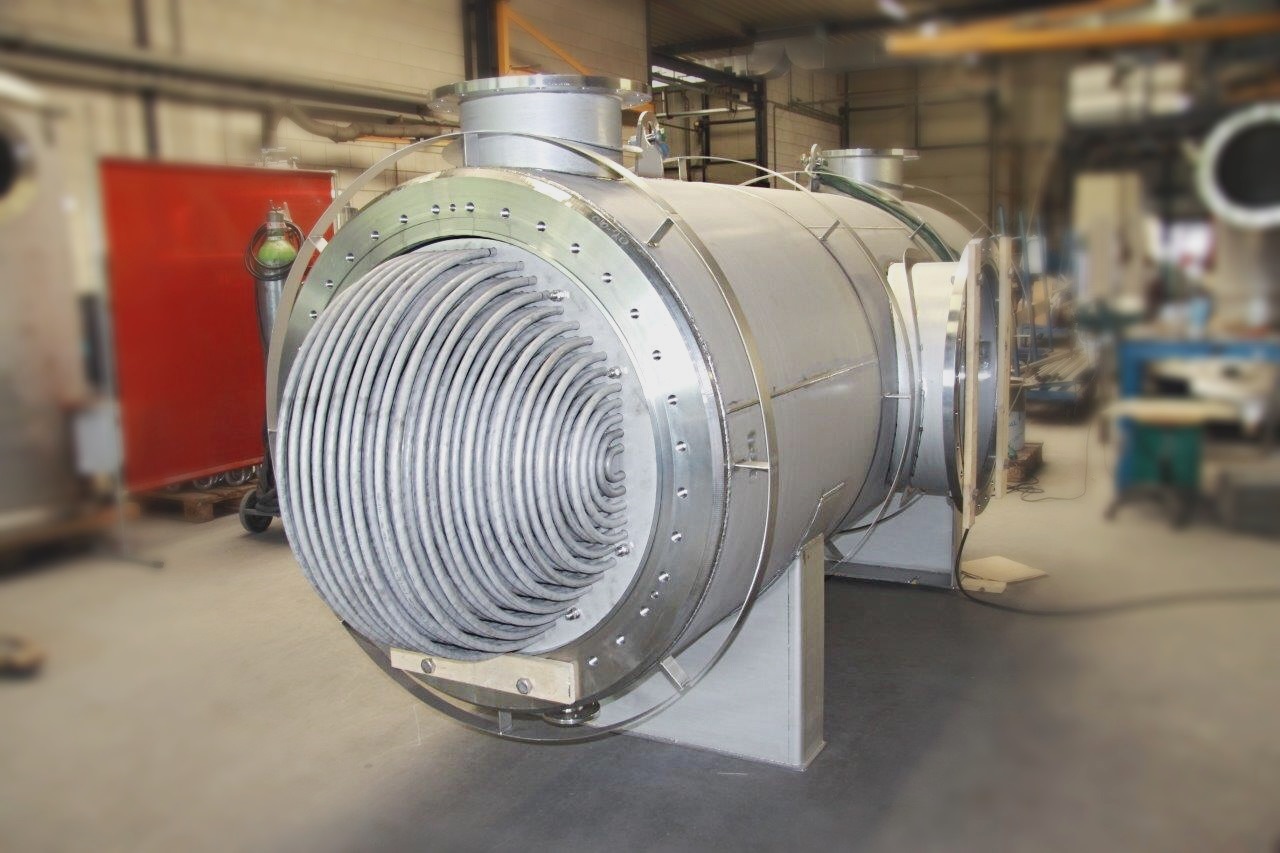

Heating and cooling

For processes such as pasteurisation and fermentation, heating and cooling of the tank are crucial. Ensure the correct combination of heating/cooling capabilities and insulation of the tank in order to heat or cool your product within the desired time frame. Let Gpi know directly what heating/cooling capacity you require, and we will collaborate with you in order to arrive at the most efficient solution, whether this concerns a dimple, a double wall or a half pipe.

Our stainless steel tanks for dairy

View the tanks and equipment that we build for the dairy industry