Storage tanks for drinks and juices

Tanks for thirst-quenchers

Whether you want to heat up, cool, mix or store your product, Gpi can supply you with the best stainless steel tanks and equipment for your production line. The shelves are filling up with an ever more varied selection of drinks. Fresh juices and sport, energy and protein drinks are becoming increasingly important. The processing of the ingredients for these products requires specialist equipment, whereby the product characteristics always need to be taken into account.

Expert in stainless steel storage tanks

Gpi has a lot of experience when it comes to building storage tanks and equipment for fruit juices, liquor, dairy products, beer or other drinks and concentrates. As a result, we are able to give the right advice on heating and cooling of products, on building tanks under pressure (PED/AD2000) in order to preserve freshness, and collaborate with you in order to arrive at the correct finish of the tank for hygienic purposes. In addition, we have good working relationships with all reputable suppliers for the right choice of agitators.

By having engineering, production and quality control in-house, we are able to supervise quality to the greatest extent possible and guarantee you solutions which satisfy the most stringent requirements in terms of hygiene, product longevity, safety and operating convenience, for both liquids and solids. Naturally, we adhere to international standards and regulations, and if required we can also manufacture our equipment according to EHEDG guidelines.

Tank/agitator combinations

We can supply the agitator as well as the tank. Gpi has a good working relationship with all reputable agitator suppliers for problem-free processing and assembly.

Finish

As a standard, we give our food-grade tanks an internal roughness of Ra 0.8. If desired, this can be increased to Ra 0.4 and the tank can be electropolished (EP).

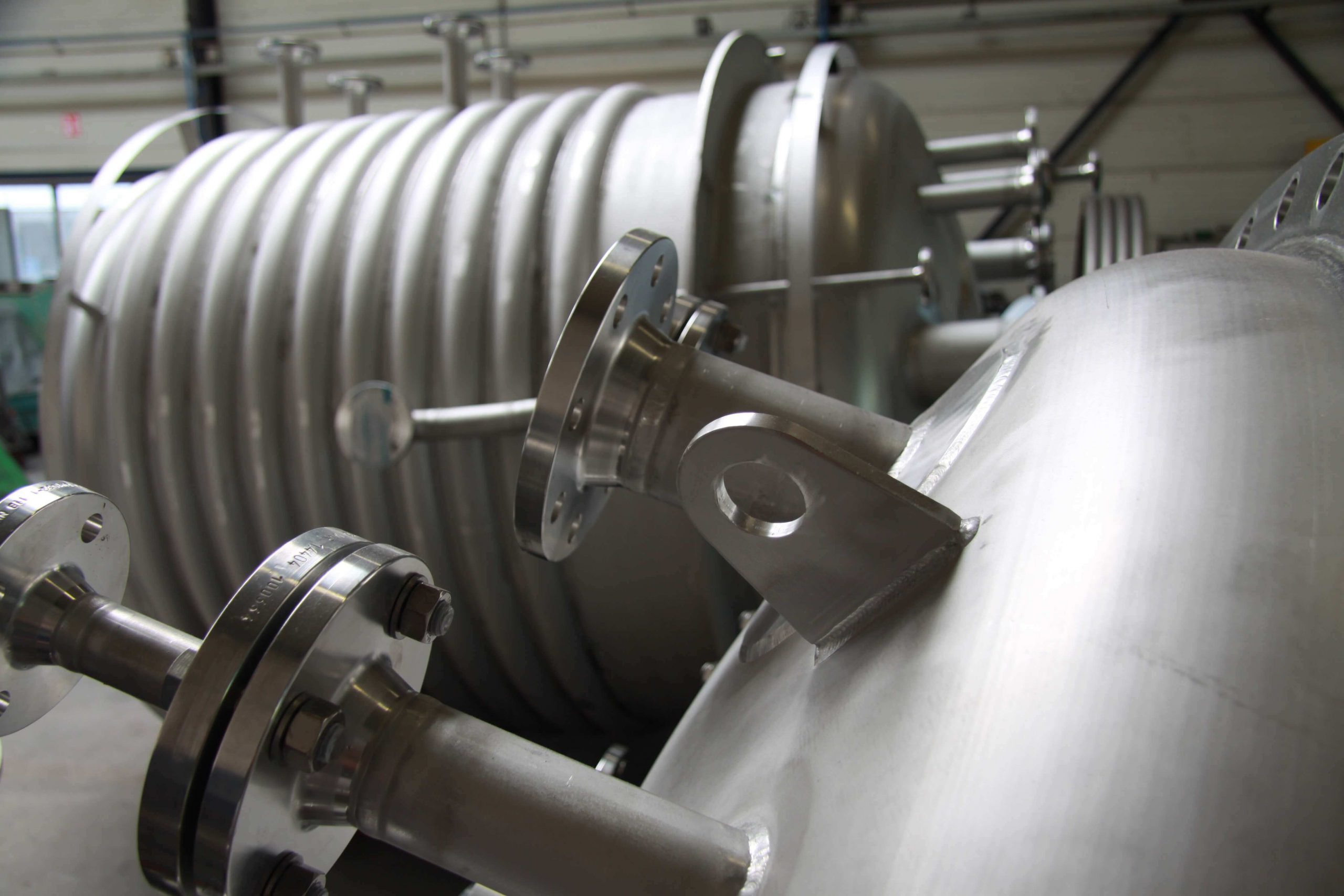

Heating and cooling

For processes such as pasteurisation and fermentation, heating and cooling of the tank are crucial. Ensure the correct combination of heating/cooling capabilities and insulation of the tank in order to heat or cool your product within the desired time frame. Let Gpi know directly what heating/cooling capacity you require, and we will collaborate with you in order to arrive at the most efficient solution, whether this concerns a dimple, a double wall or a half pipe.

Fruit juice tanks

Producers of juices, beverages and drinking water are developing their production lines and storage facilities. Most companies invest in tanks that are hygienic, durable and will serve for many years, thus not exposing the entrepreneur to additional costs.

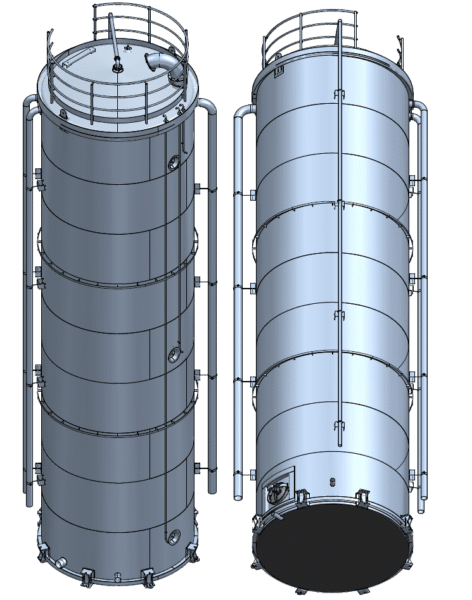

Gpi’s experience in the production of juice and water tanks is huge. Customers rely mainly on large storage tanks based on a reinforced concrete slab, designed to safety standards by a dedicated builder.

What we offer as part of cooperation:

- Aseptic tanks

- Process tanks and mixers

- Storage tanks

- Pressure tanks

- Tank with cooling and heating system

- XL tanks built at the customer’s site

- Platforms, platforms, ladders, railings

- Internal and external tanks on legs, pedestal or supporting structures

- Detailed technical documentation, 3D design, advanced design calculations, material certificates

- Efficient delivery and assembly

- Dedicated Project Coordinator

Pasteurization tank

Your company is a juice producer and needs durable pasteurization, storage and dosing tanks? The stainless steel tank is the best solution. Gpi products can store juice solution, concentrate as well as fermented fruit and wine.

Drinking water tanks

Stainless steel tanks for water are used by the food and beverage industry because they are resistant to temperature changes, corrosion, environmental factors such as wind, snow, sunlight.

The tank insulation is most often made of mineral wool, additionally protected by qualified insulators with a trapezoidal sheet facade. Tanks are designed according to the standard applicable in a given country and indications of the ordering party.

The nozzles and elements inside the tank, in contact with the product, are also made of stainless steel, usually 304, which guarantees long-term use of the tank.

Individual design

As a tank manufacturer, Gpi is ready for individual and often atypical projects. We try to use every possible storage space at our client’s. The tank is manufactured in one of our plants in the Netherlands or Poland.

It is possible to build the tank on site – at the contracting authority’s plant. This is a particularly advantageous option if it is not possible to transport the tank, e.g. due to large dimensions or bottlenecks.

Engineers will read your technical documentation and suggest the best solution.

Our stainless steel tanks for drinks and juices

View the tanks and equipment that we build for this industry