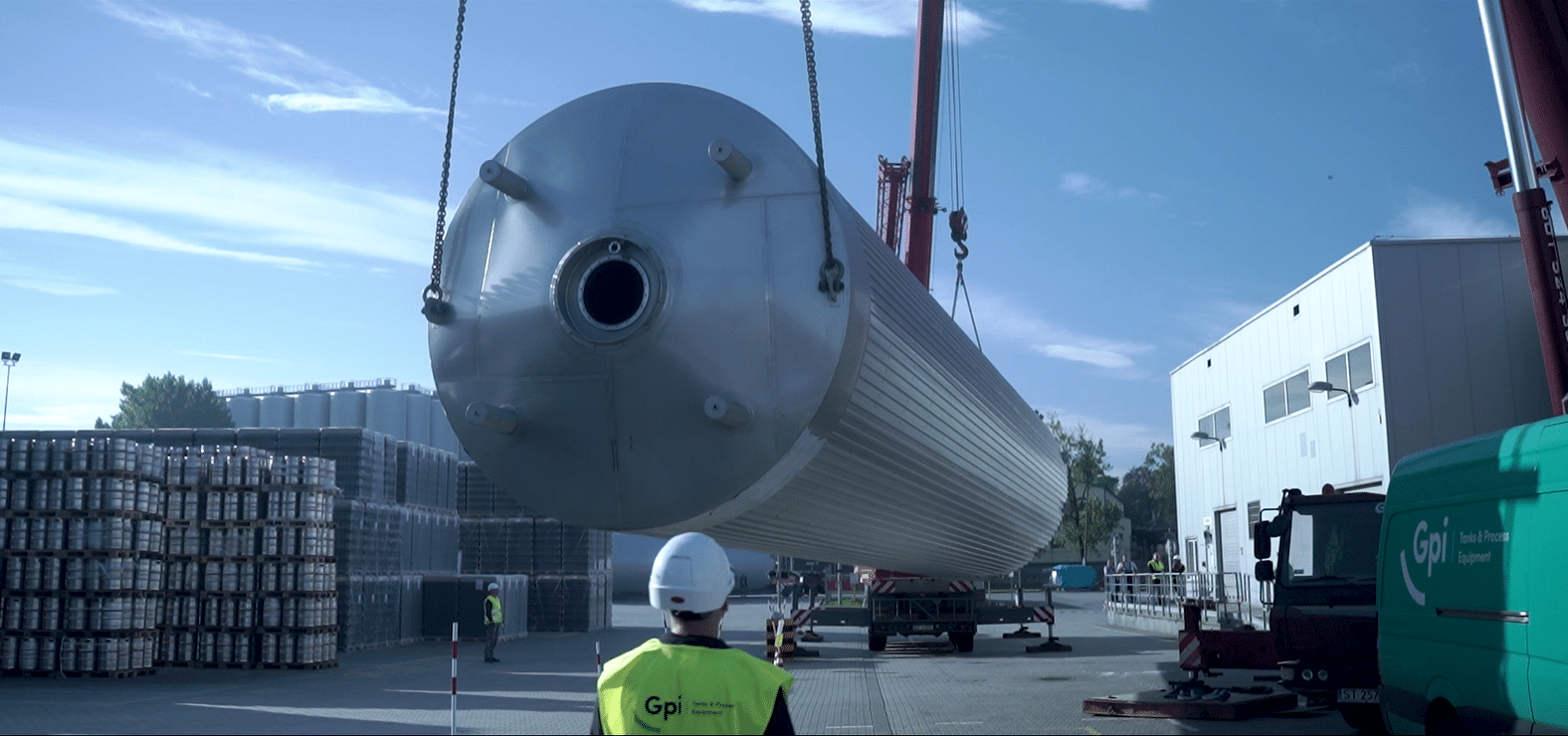

Cylindrical Conical Tank (CCT)

Fermenters for beer

CCT Tanks (Cylindrical Conical Tank)

Cylindrical conical fermentation tanks are mostly used for fermenting beer. Here, the yeast can settle in the cone at the end of fermentation and be easily separated from the young beer for clean phase separation during yeast harvesting. For procedural reasons, an internal cone angle of 60 -70° has become established. This also makes the tanks suitable for producing beer in the 1-tank process. For fermentation tanks made of stainless steel, Gpi supports you in the selection of the suitable material and the optimal equipment. In this way, we realise the right tank for your brewing process.

Design according to customer requirements

Like all tanks manufactured by Gpi, the cylindroconical fermentation tanks are also customised for your specific requirements.

The design is based on your specifications for pressureless fermentation or for main fermentation under counterpressure. The volume is aligned to your brew size. Taking into account the required rising space, the minimum volume of the stainless steel fermentation tank should be one brew size. But the spatial conditions of your fermentation cellar are also taken into account in the dimensioning. And this is done in such a way that the optimum ratio of diameter to height is achieved with the best utilisation of the available space. Stainless steel fermentation tanks can be manufactured with a volume of 50 hl to 5,000 hl.

Production of cylindroconical fermentation tanks

The fermentation tanks have a surface roughness of RA ≤ 0.8 µm as standard. Should your process require it, all stainless steel fermentation tanks from Gpi can also be fully ground or electropolished on request to achieve a surface roughness of up to RA ≤ 0.5 µm. The material for O-rings and seals is used according to your specifications.

In order to dissipate the heat generated during fermentation and to be able to control the fermentation temperature, the cylindroconical fermentation tanks can be manufactured with several cooling zones or complete jacket cooling. The cooling can be implemented as a thermoshelf, with half pipes or as a double jacket. To minimise energy losses during cooling, the tanks can also be insulated with PUR foam or insulating wool.

Do you have any questions about our beer tanks?

Equipment

Cylindrical conical tanks made of stainless steel can be supplied with a manhole on request. This allows the tank to be cleaned manually. In addition, a spray ball can be included to integrate the tank into the CIP cleaning process. Furthermore, Gpi tanks can be supplied with a nozzle for temperature measurement to control the cooling as well as with nozzles for level control.

At the customer’s request, a flange for mounting a safety valve at the head of the fermentation tank can be designed. Depending on the size of the fermentation tank and the installation situation in your brewery, the cylindroconical fermentation tanks are delivered on feet or with claws.

Specifications

- 50 hl tot 5.000 hl biertanks

- Conische bodem

- Koeling dimple plate

- Geïsoleerd

- Headspace >20%

- Hygiënisch ontwerp

- RA 0,8 of gladder

Options

- Top isolatie

- Iglo/Topplate cover

- Dimple/Halfpipe

- Conisch mangat in bodem

- Isolatie Pur/Wol

Read more about what we offer for the beer industry here.