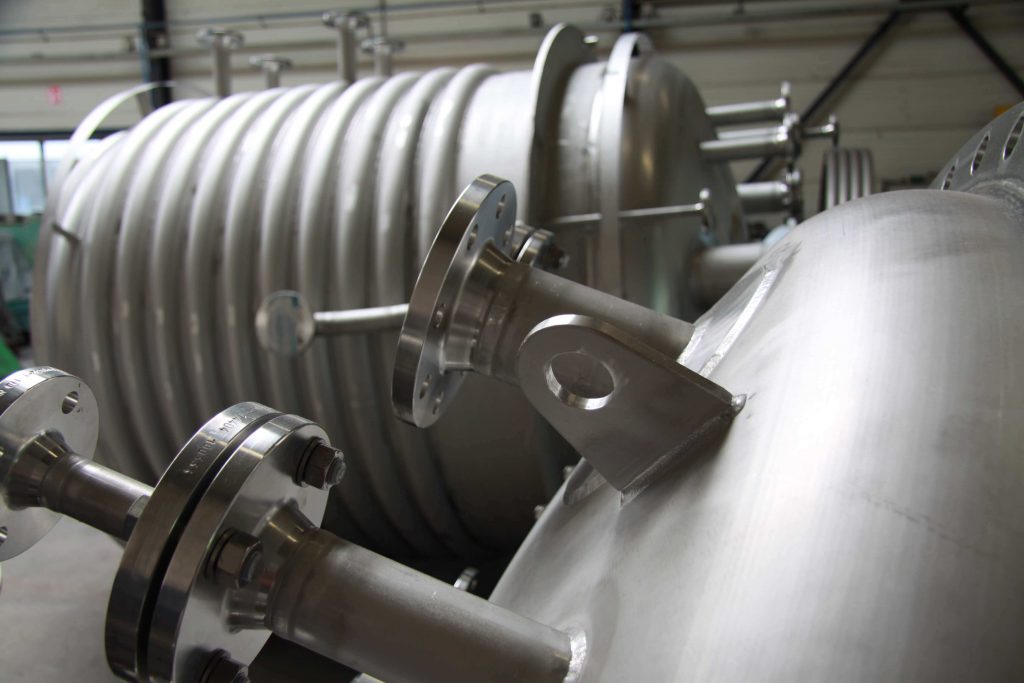

Chemical vessels and tanks

Stainless steel chemical tanks

Heat, acid, steam: chemical tanks and chemical (pressure) vessels have to withstand exceptional stresses. That is why our engineers utilise high quality stainless steel grades in the manufacturing process. This ensures that the vessels can withstand the chemicals in a wide variety of processes – from water treatment to producing cleaning agents. Gpi Tanks’ storage tanks and chemical vessels fulfil all of the industry requirements, standards and process certifications.

Safety and quality

The chemical industry has demanding quality and safety standards. This is all in a day’s work for our engineers – and has been for more than 25 years. We manufacture individually designed chemical vessels that meet this industry’s demanding standards and specifications. Gpi is certified by KIWA to design and produce customer-specific tanks in accordance with KIWA standards. The options also include chemical vessels such as PED-certified pressure tanks, reactors, stainless steel tanks to EN13445, AD2000 and flat bottom tanks to EN14015 or API650. You have the choice – we have the expertise.

Do you have any questions about our chemical tanks and process vessels?

Order chemical vessels

You will never find the term “standard” in our dictionary. We develop each tank individually and it is precisely tailored to your needs. That is why every order begins with a detailed consultation. Which requirements have to be fulfilled? Which norms have to be observed? Once all of the specifications have been documented, we design a prototype. How? With our innovative design program developed in-house.

After you have granted your approval, our engineers develop the detailed technical drawing and then produce the chemical process vessels or storage tanks. Naturally, for larger orders, you will have access to your own dedicated project manager who will supervise the process from design to production and delivery onward to the installation – and who can draw on more than 25 years of experience in tank and vessel construction.

Chemical tanks in every size, for every application

What are your requirements? This a central question. We only commence planning the project when this crucial question has been fully answered. Why? The possibilities are virtually limitless. Therefore, our engineers have to know what they are designing, manufacturing and what it will be used for from the outset. Here are a few examples:

- Tank with agitator

- Heating/cooling

- Insulation

- Vessel with manhole/inspection openings

- Mobile pressure and process vessels

- CIP tank

- WFI tank

- Tank construction on site

Contact us and enquire about the possibilities for your plant with no obligations.

Resistance to aggressive environment

Gpi is one of the leaders in the production of acid-resistant and heat-resistant steel tanks for the chemical industry. In aggressive environments with acids and chemical compounds, the resistance of stainless steel is important. Only the high quality of the materials from which the tanks are made is able to withstand the potential impact of chemical, physical or electrochemical properties. We approach our clients’ requirements individually, ensuring professionalism, precision of workmanship and guaranteeing safety. These activities are necessary especially in the case of chemical tanks.

Stainless steel in the chemical industry

Due to its durability, non-corrosive properties and versatility in use, stainless steel is the most commonly used material in the chemical, pharmaceutical and paper industries. 304L steel is highly resistant to most oxidizing acids. AISI 304 is resistant to most organic chemicals and dyes, sterilization solutions and inorganic chemicals.

High-alloy steels from the group of super-austenitic, super-ferritic and duplex alloys are increasingly used in industries associated with corrosive and hazardous substances.

Refining industry and duplex steel

In the case of the interaction of naphthenic acids, the highest resistance is demonstrated by the austenitic steel grades from the 316L group, to a much higher degree than the ferritic grades. In the most aggressive environment, high-alloy austenitic steel, duplex or super duplex steel (1.4462, 1.4460, 1.4501, 1.4507) and super ferritic steels are used.

Lean duplex steel is more and more often used for chemical, caustic and hazardous substances, which allows lower material costs compared to classic duplex steel, where high mechanical properties and corrosion resistance are maintained at the same time. In refining units, the duplex steel used in the construction of storage tanks makes it possible to reduce the need for material, while reducing the costs of the tank itself.

More about duplex steel for the chemical industry >> here

Stainless steel chemical tanks – what should you know?

- Chemical tanks are produced in a vertical or horizontal version in a capacity selected by the customer, in accordance with the standards in force in a given country and according to the customer’s indications,

- At Gpi, we use AISI 304 or AISI 316L stainless steel, Duplex depending on the stored substance and the desired tank capacity,

- We can build large tanks for chemicals on site, at the customer’s factory,

- Gpi provides railings, ladders, landings and other infrastructure elements,

- The tank surface can be insulated by experienced Gpi insulators,

- Pressure vessels for the chemical and food industries are very popular,

- Pressure vessels can be designed and manufactured in accordance with ASME certification

- Stainless steel tanks are completely resistant to weather conditions,

- Gpi provides all the technical documentation and helps with formal issues, such as acceptance of the tank by the Office of Technical Inspection.