Food tanks

Are you looking for a hygienic and reliable solution for storing and processing your food and beverages? Then Gpi Tanks is the right address for you. We manufacture and supply stainless-steel tanks suitable for a wide range of applications including raw milk tanks, cream tanks, fish oil tanks, edible oil tanks and crystallizers. Our engineers will work with you to develop the perfect design for your aseptic tanks to keep your products safe and sound. Contact us today to learn more about our food tank solutions.

Gpi Tank quality

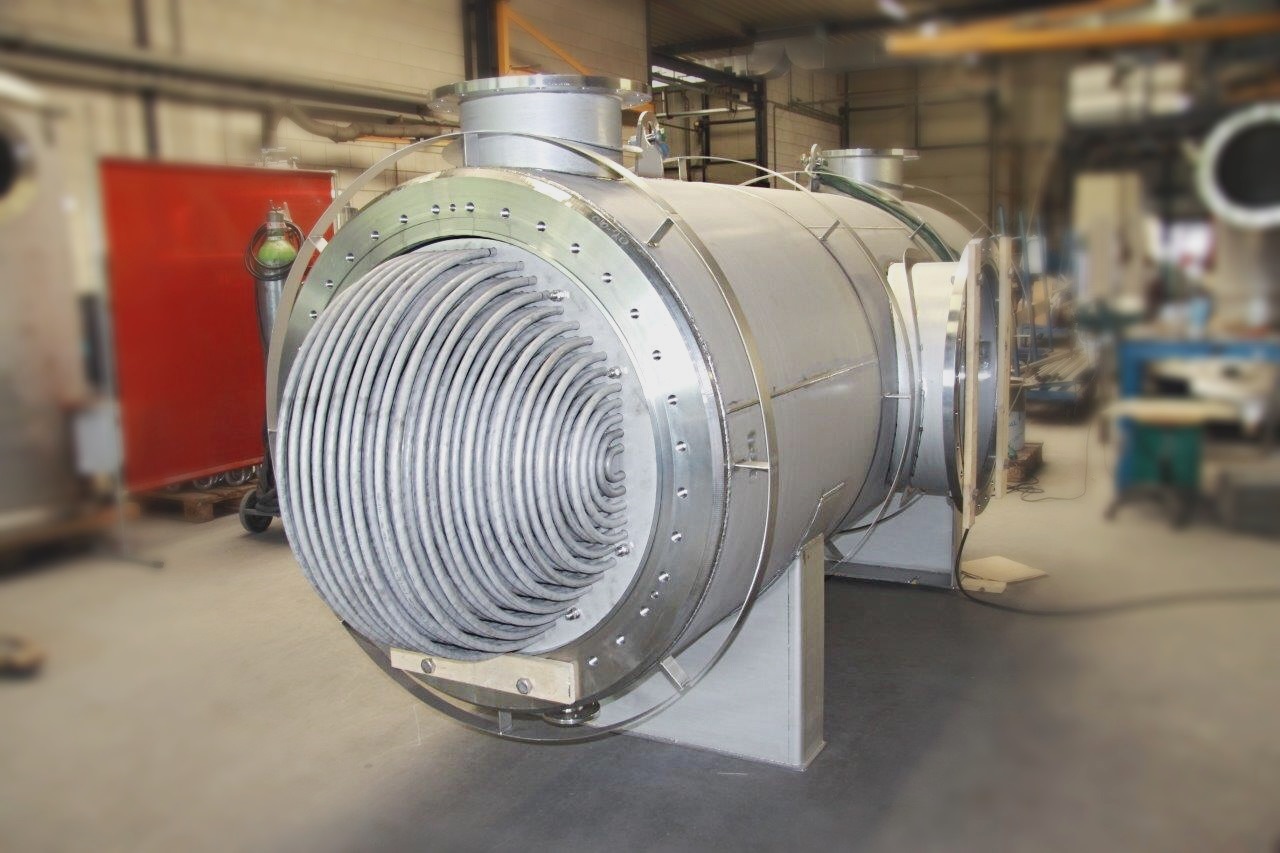

At Gpi Tanks, we specialize in high-quality stainless-steel food tanks for a variety of industries. Our tanks are designed to meet the rigorous demands of the food industry, providing reliable protection for your products and ensuring that your storage needs are fully met. Stainless-steel food tanks, designed, manufactured, and delivered by Gpi Tanks are the ideal solution for storing and processing food products. These tanks feature a highly hygienic grade construction, and incorporate an efficient agitation system to ensure the quality of the product. They also feature external insulation to minimize heat loss, making them an efficient and reliable choice for storing all types of food products.

Stainless-steel tanks for the food industry

Some of the subcategories that you might find when researching stainless-steel food tanks include juice tanks, raw milk tanks, cream tanks, edible oil tanks, fish oil tanks, and crystalizer tanks. These tanks are designed specifically to preserve and protect the flavor, taste, and nutritional properties of various food products.

We fabricate all types of food storage tanks, processing raw materials and finished food products. When choosing a tank for storing food products, it must be borne in mind that there are certain rules for storing products that will subsequently be eaten. This means that the contents of the tanks should not deteriorate and change their taste, nutritional and other characteristics when interacting with the container. And also, tanks for food products must comply with sanitary and hygienic standards and provide reliable protection of products from the influence of external factors.

Why choosing Gpi Tanks?

Whether you are looking for storage or processing solutions for your industry, Gpi Tanks will customize stainless-steel food tanks to meet your needs. So, why not explore our selection today and find the perfect solution for your business?