Pressure vessel

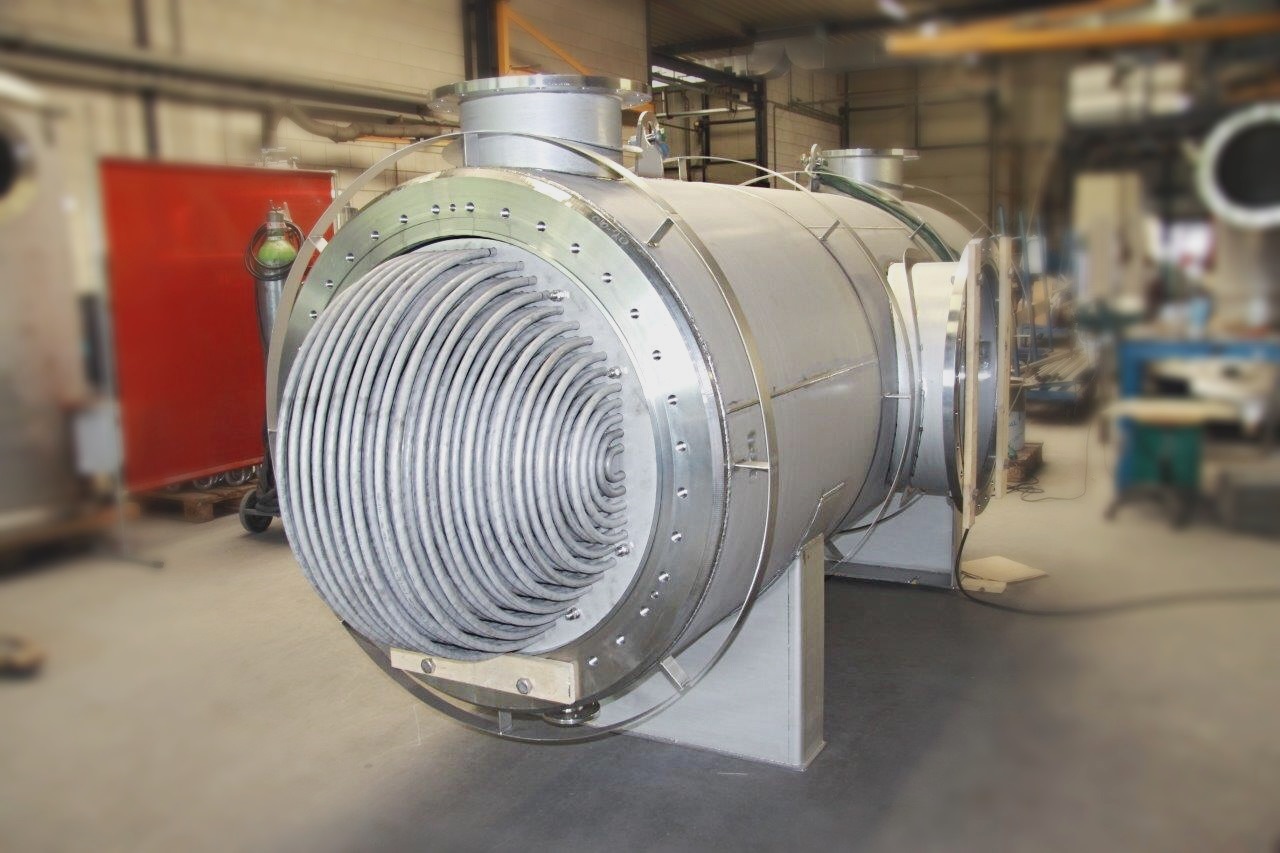

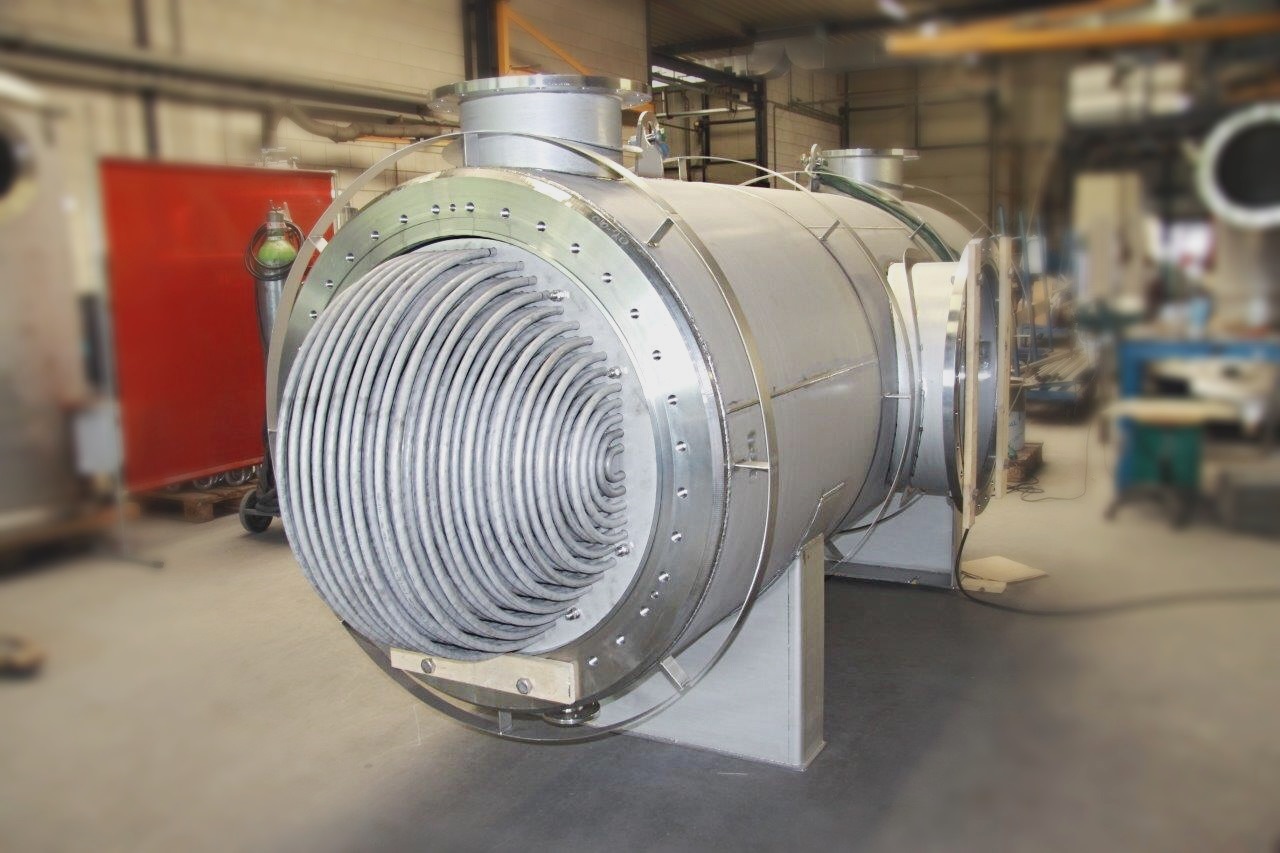

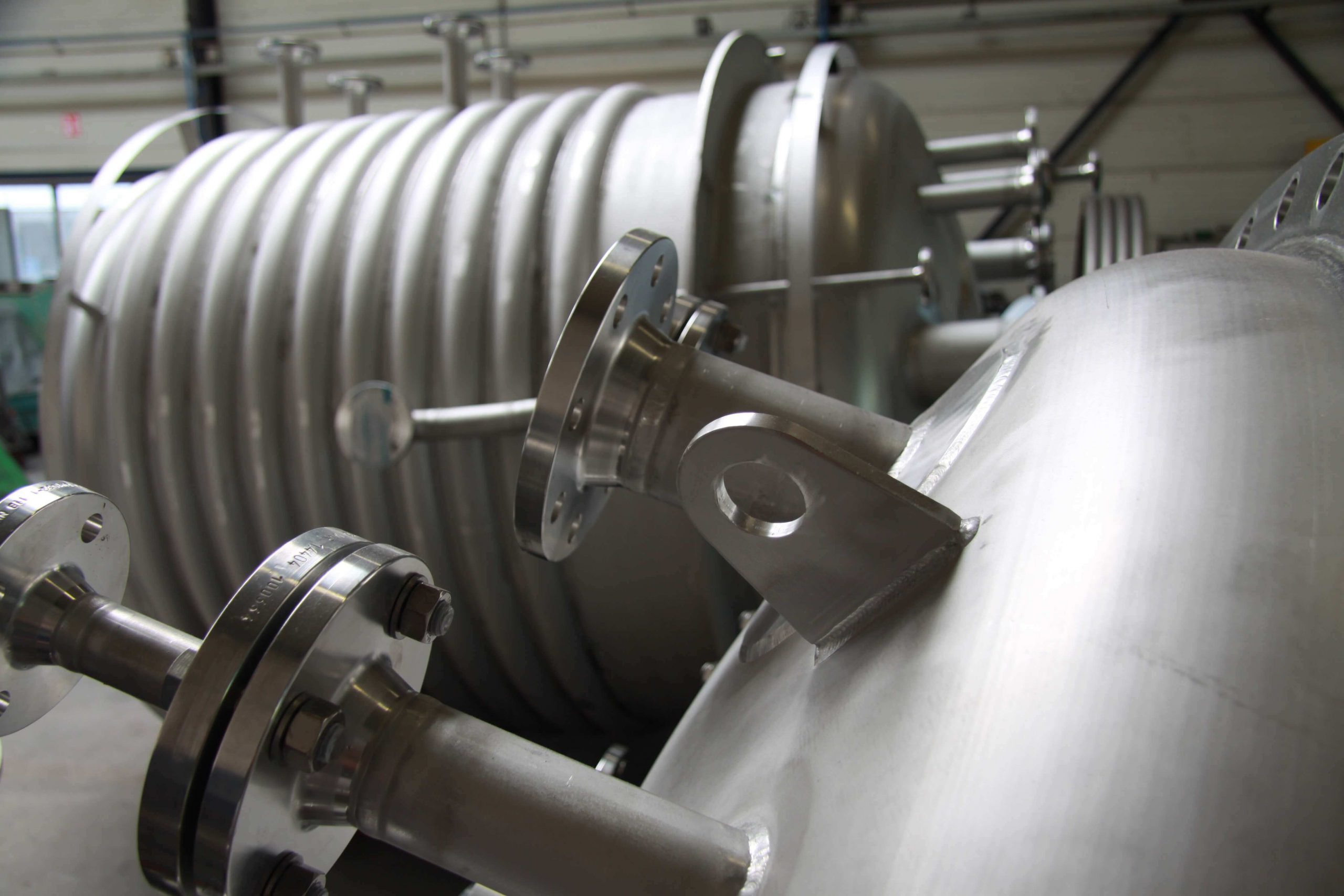

Pressure vessel PED-certified stainless steel pressure tanks Design and production of pressure...

Read moreChemical, mechanical or physical processes occur in all industries. Tanks are almost always involved in this. We have the knowledge needed to turn the required process into an efficient and effective tank design.

Pressure vessel PED-certified stainless steel pressure tanks Design and production of pressure...

Read more

Storage tanks for drinks and juices Tanks for thirst-quenchers Whether you want...

Read more

Pressure vessels EN 13445 Stainless steel tanks with European standard Standard applied...

Read more

Pharmaceutical tanks Stainless steel process and storage tanks Hygienic surface finish For...

Read more

Pressure vessel Stainless steel pressure vessel from 0,5 bar Lloyds audited Gpi,...

Read more

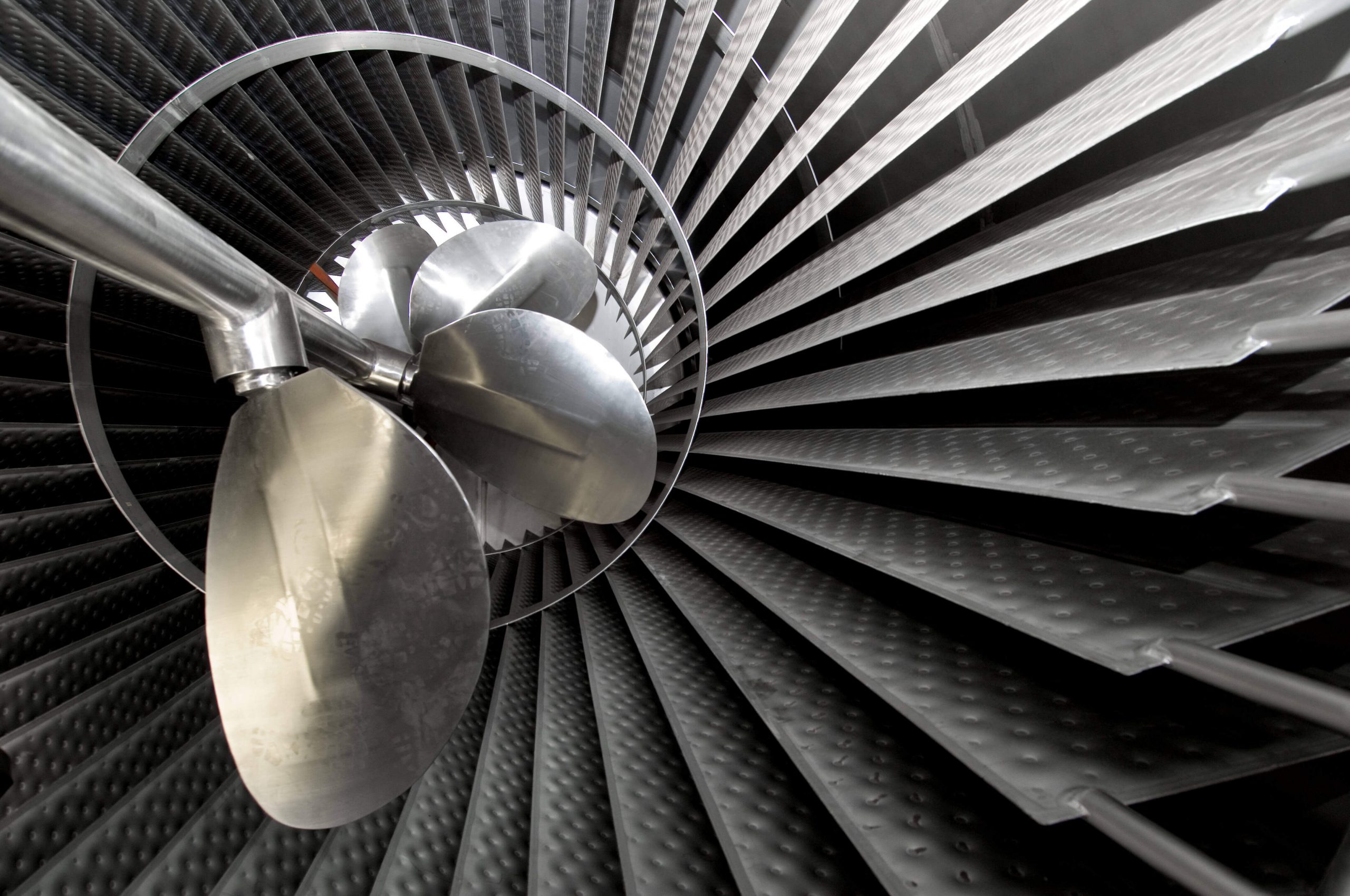

Crystalliser Developments in crystalliser technology Ever stricter quality standards in the food...

Read more