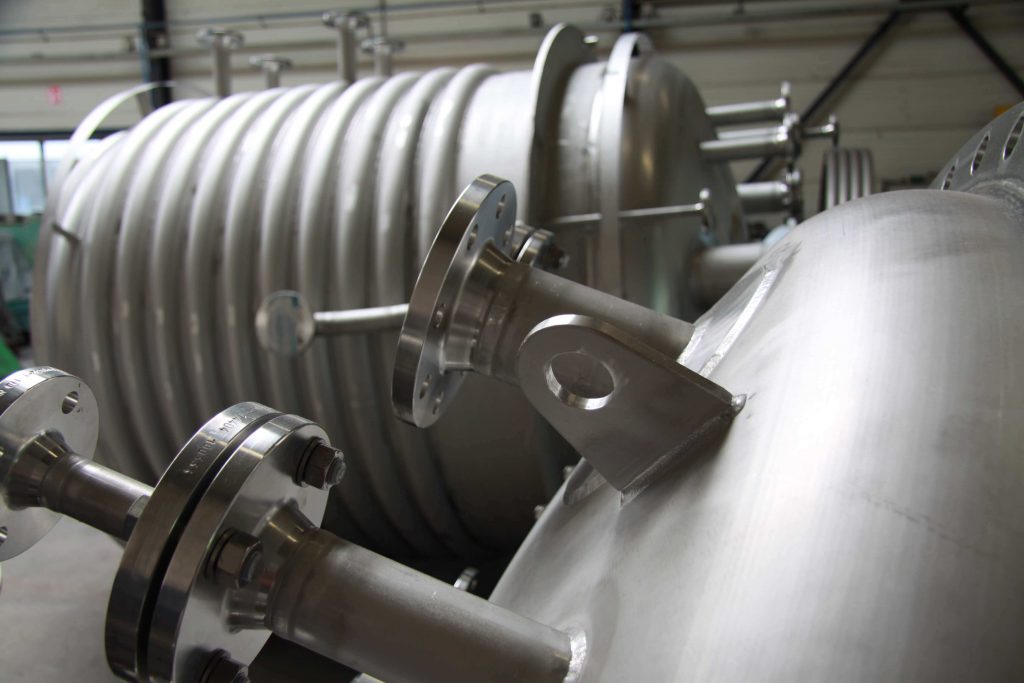

Stainless steel storage tanks

Stainless steel tanks from 500 litres to 15,000 m3

Stainless steel tanks in all sorts of sizes

Gpi produces all kinds of storage tanks in all sorts of sizes for all applications and industries imaginable. This range spans high-quality finished 500 litre vessels for pharmaceutical end products, to 15,000 m3 tanks for drinking water or the storage of semi-finished products in the chemical industry.

Stainless Steel tanks for storing high-quality products

Gpi manufactures stainless steel storage tanks from 500 l to 15,000 m³. Depending on the destination, we can build the tanks in our factory in Lopik, in our factory in Groot-Ammers, or construct them on-location. We produce high-grade tanks and storage tanks up to a diameter of 6 m at our Lopik facility. From there, we can reach most locations quickly by road.

Do you have any questions about our storage tanks?

Types of storage tanks

Oil tank

The right oil storage tank is very important for the storage of oils and fats. Oils are at the basis of many products, both for food and cosmetics and for the pharmaceutical or chemical industries. We produce your oil storage tank from stainless steel. Any size of oil storage tank is possible.

Milk tank

Stainless steel milk tanks come in many shapes and sizes: from storage tanks for raw milk to cheese milk and VLOG milk. For each stainless steel milk tank we can make specific designs for the right processing. Read more below about possibilities for agitators, crystallization, insulation etc. There are also endless possibilities for storage tanks for other types of dairy.

Silo

In addition to storage tanks, which are generally used for storing liquids, we also produce stainless steel silos. Silos are used for dry storage in almost every industry: for storage of food, pharmaceutical and cosmetic products to storage of animal feed, building materials, plastics and other chemical products. Silos, often stainless steel conical tanks, require an individual design. We produce your stainless steel silo to measure and with the required specifications. We take care of the entire silo construction: from the customized design by our own engineers to the construction and transport. Our silo builders have experience in producing for example pellet storage silos.

Beer tank

For the storage and production of beer, we build both storage tanks and process tanks. A bright beer tank is a stainless steel beer tank for the storage of filtered beer. Are you looking for a stainless steel conical tank, such as a fermentation tank? Read more about bright beer tanks (bbt) and cylindrical conical tanks for fermentation (cct) on our page about beer tanks.

Water storage tank

We have produced various water storage tanks in recent years. From a hygienic design for demineralized water, for example, to a water tank for contaminated waste water from a chemical plant that must, for example, comply with guidelines for soil hazardous liquids, flammable substances or other hazardous liquids.

Other storage tanks

We produce for all industries, so customized storage tanks for any application.

Specifications/ additons for storage tanks

Each application requires its own specifications and additions. For a hygienic design, we think along with you about the right connections and agitators, but we can also add cleaning equipment. Various choices for a particular top and bottom are possible: conical, flat or sloping, open, convex, etc. Each of these options also offers different possibilities. We also supply double-walled tanks with insulation. Our experts can advise you on the right type of jacket and insulation.

In every storage tank design we take into account the minimum and maximum design pressure, liquid tightness, minimum and maximum temperature, correct placement of connections, manhole hatches, external design loads, loads from agitators, impact on the legs caused by movement of the liquid in the tank and the platform.

Standards for stainless steel tanks

Specific standards, laws or regulations often apply to storage tanks.

PGS 29, NEN-EN14015, Eurocode 3, API 650, DIN 4119

If a PGS 29 regime applies to your installation in the Netherlands (the guideline for above-ground storage of flammable fluids), your tanks usually have to comply with NEN-EN14015 in combination with Eurocode 3. Please note: PGS29 recently changed. Gpi can tell you what this entails for you.

Other standards which Gpi often applies for storage tanks are API 650 and DIN 4119. Naturally, we can also be of assistance if PGS30 or PGS31 apply to your installation.

PED pressure vessels according to NEN-EN13445

Lloyds audited Gpi, and accredited the company to independently design and manufacture pressure tanks over 0.5 bar (H + H1 certified). If your storage tank is part of a PED installation, the project engineer will closely collaborate with the client and our own QA/QC employee in order to carry out a risk analysis and set up a test & inspection plan. These tanks are usually designed to be in line with NEN-EN13445.

KIWA BRL-K756 storage tanks

This is just a selection of our options. If your building code or regulation is not listed here, then contact Gpi.